10 Size Chart Mistakes That Cause Returns (And How to Fix Them)

These common errors are costing you money. Learn what to avoid and how to fix existing problems.

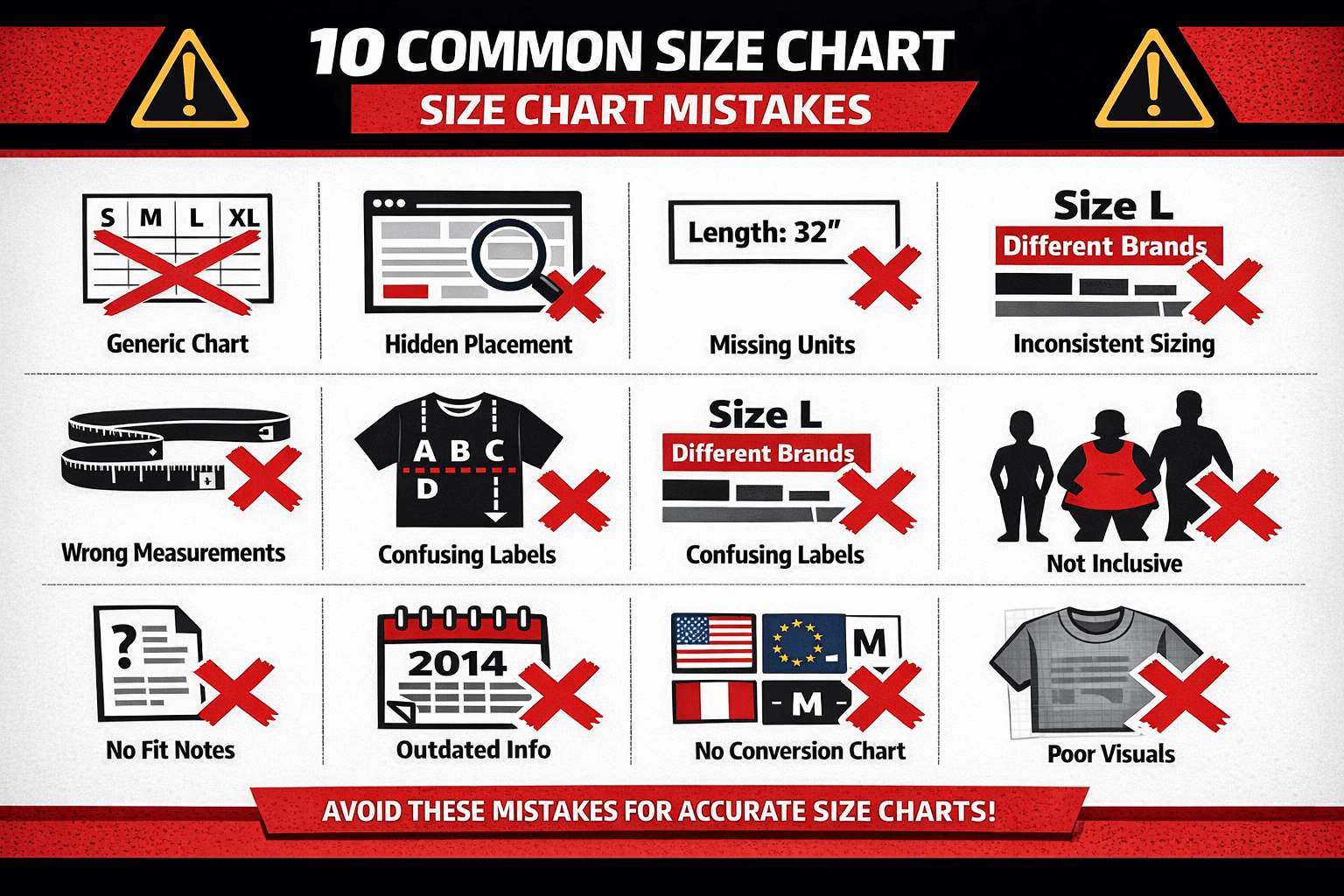

The 10 Biggest Size Chart Mistakes

Using Generic Size Charts

Copying standard size charts that don't match your actual products.

Fix: Measure your actual garments or use AI-powered tools.

Not Specifying Units

Missing "inches" or "cm" labels, leaving customers guessing.

Fix: Always label units clearly. Show both when possible.

Hiding the Size Chart

Burying size info where customers can't find it.

Fix: Place prominent "Size Chart" link near the add-to-cart button.

No Measurement Diagrams

Customers don't know where measurements are taken.

Fix: Include visual diagram showing measurement points.

Outdated Information

Not updating charts when suppliers or patterns change.

Fix: Review and update charts quarterly. Date-stamp changes.

Missing Fit Description

Not explaining if item is slim, regular, or relaxed fit.

Fix: Always include fit type and what it means.

Poor Visual Design

Hard-to-read fonts, low contrast, confusing layouts.

Fix: Use clear typography, high contrast, logical organization.

No Tolerance Ranges

Presenting measurements as absolute numbers.

Fix: Include ±0.5" or ±1cm tolerance for manufacturing variance.

Not Mobile-Friendly

Size charts that are impossible to read on phones.

Fix: Optimize for mobile with scrollable tables or responsive design.

Inconsistent Across Products

Medium means different things for different products.

Fix: Standardize sizing across your catalog or clearly differentiate.

FAQ

What are the most common size chart mistakes?

Generic charts, missing units, hidden placement, no diagrams, outdated info, missing fit descriptions, poor design, no tolerances, not mobile-friendly, and inconsistent sizing.

Why is using a generic size chart bad?

Generic charts don't match your actual products. A customer following a generic Medium might receive something completely different.

What is tolerance and why include it?

Tolerance (±0.5") acknowledges manufacturing isn't perfect. It sets realistic expectations and reduces complaints.

How often should I update size charts?

Update when suppliers or patterns change. Review all charts quarterly. One outdated chart causes ongoing problems.

Create Error-Free Size Charts

Generate professional, accurate size charts that avoid all these mistakes.

Try for Free